首页 >Business

CATL Supplier BANGQl TECH Bets Big on Al-Driven Unmanned Factories,Promising 50% Labor Cost cuts

2025-05-19 14:48:02

来源:互联网

On May 15, the 17th China International Battery Fair (CIBF) officially opened at the Shenzhen World Exhibition & Convention Center. With the theme “Green Energy Powers the Future”,the event showcased a comprehensive array of advancements across power batteries, energy storage batteries, 3C batteries, battery materials, manufacturing equipment, and power and storage system solutions — spotlighting the latest breakthroughs in battery technology and new energy storage.

As a global leader in unmanned factory innovation, BANGQI Technology made a striking appearance at the exhibition, debuting its BANGQI Mobile Robot Matrix and eight pioneering full-scenario unmanned solutions for the new energy sector. Through on-site demonstrations, BANGQI showcased how its AI-driven automation solutions can digitally upgrade key stages in battery manufacturing. The presentation drew significant interest from domestic and international attendees, becoming a highlight of this year's event.

With the rapid growth of the new energy industry, demand for power and energy storage battery production capacity has surged. However, manufacturers continue to face challenges such as labor-intensive operations, fluctuating yield rates, and inefficient logistics. Addressing these shared pain points, BANGQI has developed a suite of eight fully unmanned, full-scenario solutions leveraging its proprietary technologies — including vertical AI micro-models, the LDS unmanned production-pull system, ADS multi-brand robot hybrid scheduling system, and MOM unmanned manufacturing management platform. Together, these solutions tackle core bottlenecks in battery manufacturing — labor management, material handling, and quality control — through a flexible, highly universal system architecture.

The eight groundbreaking full-scenario unmanned solutions introduced by BANGQI include:Automated Dock Loading/Unloading;Automated Battery Material Unpacking;Foil Unpacking Automation;Automated Overhead Transport (OHT);Overhead Material Delivery Systems;AI Visual Quality Inspection;Smart Storage & Retrieval for Auxiliary Materials;Factory-wide Autonomous Driving.

Among these, the Automated Dock System integrates technologies such as rail-guided forklifts, wing-opening vehicles, and tailgate AGVs to achieve seamless cargo transfer with zero waiting time — significantly improving logistics efficiency and space utilization. The battery material and foil unpacking systems leverage intelligent recognition and mechanical operation to solve low-efficiency, high-contamination, and error-prone issues in manual unpacking.

The OHT and overhead conveyor systems overcome traditional ground logistics constraints, ensuring high cleanliness and stability during material transport. The AI visual inspection system enables precise appearance checks and structural recognition, dramatically reducing missed and false detections. Additionally, the smart storage and retrieval systems and autonomous driving solutions across the factory grounds further strengthen intelligent operations in new energy manufacturing.

According to data,BANGQI’s AI unmanned solutions can increase overall automation rates by 50%, boost capacity by 10%, reduce labor costs by 50%, and cut hardware investment costs by 30% — empowering manufacturers with enhanced cost control and product consistency. Leading clients have reported significant improvements in line stability, flexible scheduling, and product yield after adopting BANGQI’s solutions.

Globally, BANGQI Technology has implemented over 1,000 projects across China, North America, Europe, and Southeast Asia. It has established deep partnerships with many global industry leaders and built a robust foundation of technological capabilities and global delivery competence — showcasing its strong position in driving AI-led digital transformation in unmanned factories.

Currently, BANGQI’s clients span across industries such as new energy, 3PL, automotive and auto parts, pharmaceuticals, 3C electronics, and cross-border e-commerce. These include CATL, EVE Energy, AESC, Sunwoda, JinkoSolar, United Automotive Electronic Systems, Joyson Electronics, Hozon Auto, Unilumin, Guangzhou Pharmaceutical, SF Express, DHL, and others — all working together to foster a global ecosystem of digital innovation.

At CIBF 2025, BANGQI Technology not only presented its cutting-edge smart manufacturing technologies but also outlined a bold vision for the future of unmanned intelligent battery factories. Looking ahead, as global manufacturing undergoes a transformative shift, BANGQI will continue to drive scenario-based innovation powered by AI, accelerating the development of fully unmanned, end-to-end solutions — and propelling the global new energy industry into a new era of intelligent manufacturing.

免责声明

【慎重声明】 凡本站未注明来源为“默认站点”的所有作品,均转载、编译或摘编自其它媒体,转载、编译或摘编的目的在于传递更多信息,并不代表本站赞同其观点和对其真实性负责。 如因作品内容、版权和其他问题需要同本网联系的,请在30日内进行!

最新文章

盛夏暑热难耐?光明乳业解锁清凉“多面派”生活

2025-08-29 10:17:57

匠心传承,古韵新生——记木雕名家龙巍的艺术人生

2025-08-29 09:28:38

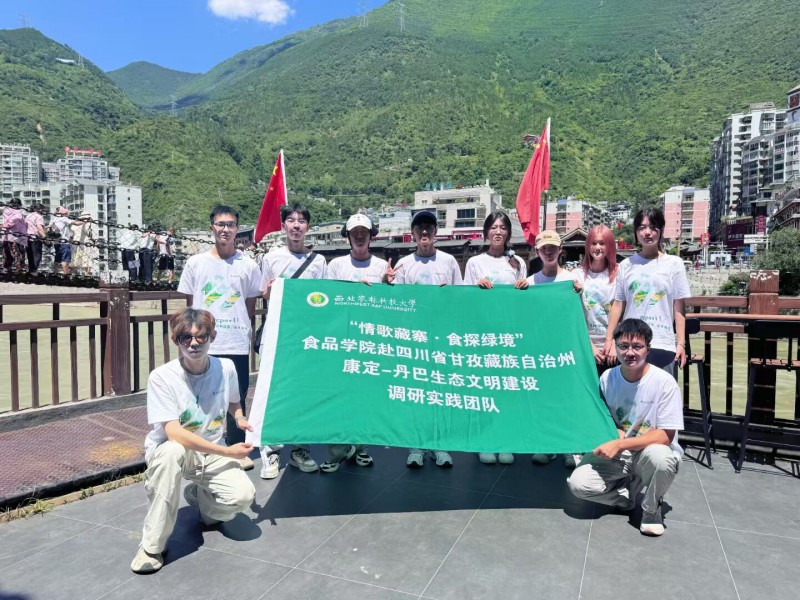

“食”力探绿·情系藏寨——西农食品学院四川甘孜实践行

2025-08-28 22:59:00